Optimization of rope force distribution in rigid rope towers by means of radio measuring axles

Operators of cranes with load guidance by means of a rigid rope tower have to change their ropes at regular intervals due to wear. Many operators apparently are oblivious of the great influence that the geometry of the rigid rope tower and its rope force distribution have on the rope service life to be achieved. Depending on the extent of the rope wear and on the interference potential of the rope change in the operating process respectively, the rope force distribution is adjusted using more or less suitable methods.

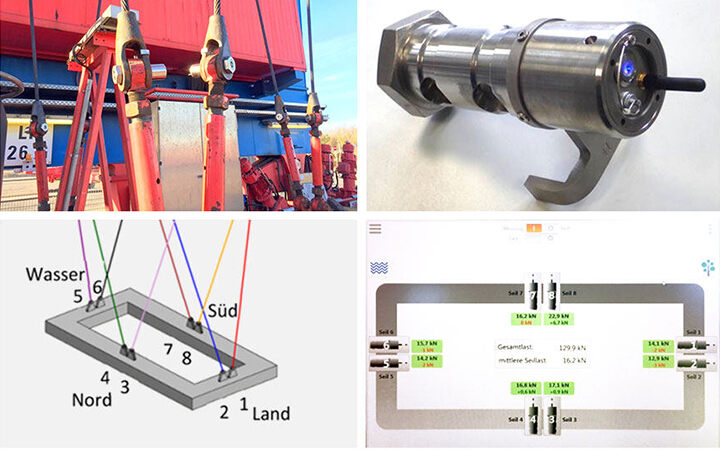

IFF Engineering & Consulting GmbH is offering rope force adjustment as a service for many years and also supplies the corresponding measuring and evaluation technology.

With our new generation of radio measuring axles and the additionally available optimization software, we have further simplified our procedure. Concurrently the accuracy of the setting can be increased, thus extending the rope service lives and reducing their variance. The radio measuring axles each have their own batteries and radio modules for transmitting the measuring signals to the measuring computer. The radio measuring axles are manufactured individually for each application. Our optimization software also significantly reduces the time which is required for the setting steps.

Technology and procedure were presented at the Kranfachtagung 2019. (download pdf-file)